- Catalog

- Fabrication Options

- Standard Fittings

Corrugated metal hose is used across a very broad spectrum of applications. Just as the hose, fittings, and other assembly parts must meet the demands of the application, so must the methods of joining these components. Pressures, temperatures and corrosion extremes may dictate special joining or fabrication techniques, including:

- Half-Corrugation. Standard fabrication sometimes leaves a portion of the cut corrugation, or corrugation “lip”, just under the base of the fitting. To prevent any exposed corrugation edges from causing damage, the hose can be specially prepared for welding by cutting the corrugation on the crest, rather than in the valley, thereby removing the lip.

- Smooth Transition. For applications with corrosion concerns, all crevices and fissures must be minimized. Specialized hose and fitting preparation, in conjunction with smooth transition welding techniques provide a full penetration hose-to-fitting weld that is smooth and crevice free.

- Braid Over. Assemblies operating at the upper limits of their rated working pressure or in severe service may benefit from braid-over construction. The fitting is first welded to the unbraided hose. Then a special metal reinforcing ring is installed over the fitting and next to the weld. Finally the braid is drawn over the end of the hose and the ring, and welded to the side of the fitting, maximizing the wire strength.

Stripwound metal hose, although not gas tight, is rugged, making it excellent for use as a guard, an open-ended exhaust hose, and for the transfer of dry bulk materials. As the name suggests, stripwound hose is made from a strip of steel that is continuously wound to form a hose. We offer four types of stripwound hose:

- Roughbore Interlocked. The strip is formed with legs that interlock to form a tighter, more rugged construction that is extremely flexible and ideally suited for open-end exhaust or a protective cover.

- Smoothbore Interlocked. Made by adding another steel strip inside a roughbore hose to provide a smooth surface, thereby reducing damage to sensitive materials and is extremely flexible; ideally suited for conveying dry, bulk materials.

- Packed Interlocked. Packing made from resilient elastomers or harder materials such as stainless steel and copper are added to interlocked hose during manufacturing to minimize leakage through the hose.

- Squarelocked. The strip is formed into square shapes that are locked together to form an extremely flexible, strong protective covering for wires, fiber optic cables, and other hoses.

Selecting the standard fittings for an application is largely determined by the mating fittings to which the hose assembly will be attached and include:

Male Pipe Nipple

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

- Schedules – 40, 80

Grooved-End Fitting

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 8″

Slip-on Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 12″

- Class – 150#, 300#

Plate Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 14″

- Class – 150#

C Stub with Floating Flange

- Alloys – T304 and T316 Stainless Steel

- Sizes – 1 1/2″ thru 10″

- Schedule – 10

Part A and Part D (Cam-Lock)

- Alloys – T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

Tube End

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 8″

- Wall Thickness – Various

Reducer

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 6″

- Schedule – 10, 40 (Carbon Steel)

Beveled Pipe End

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

- Schedules – Various

NPSM Female or Male

- Alloys – T304 Stainless Steel

- Sizes – 4″ thru 6″

Tar and Asphalt Male and Female

- Alloys – Malleable Iron

- Sizes – 1 1/2″ thru 4″

Compensator

- Alloys – Urethane

- Sizes – 3″ thru 6″

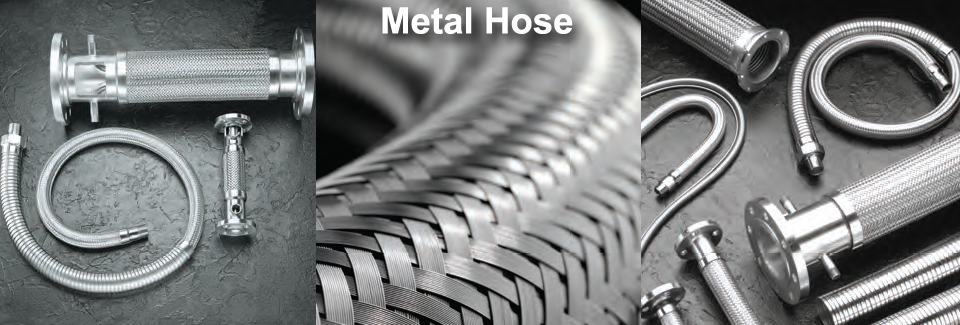

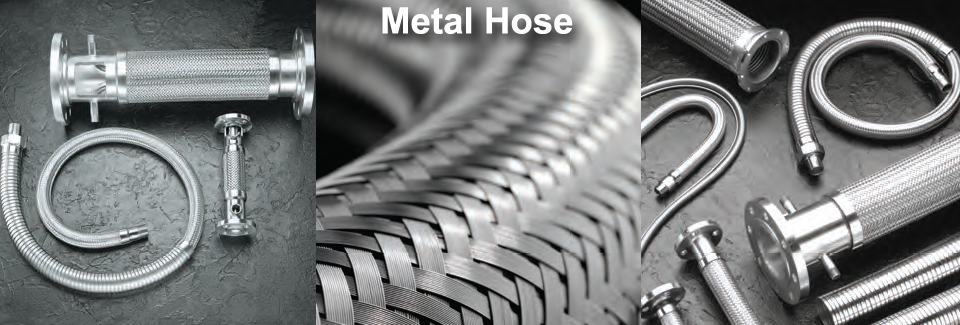

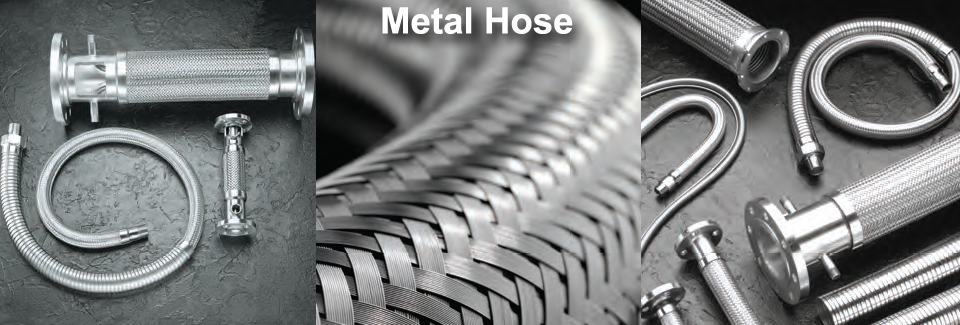

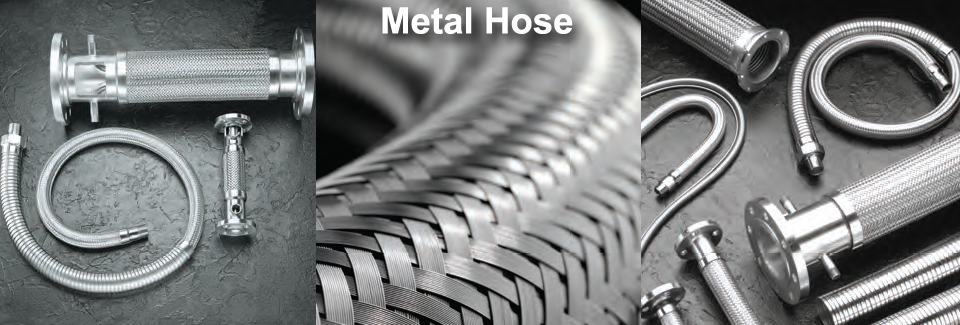

Corrugated metal hose can handle high pressures and is gas tight. It is excellent for gas and liquid transfers. To give corrugated hose the ability to withstand pressure, stainless steel wire is braided over the hose. Hoses may be single braided (one layer of braid) or double braided (two layers of braid) to achieve even greater working pressures – and braided braid is used on large-diameter hose.