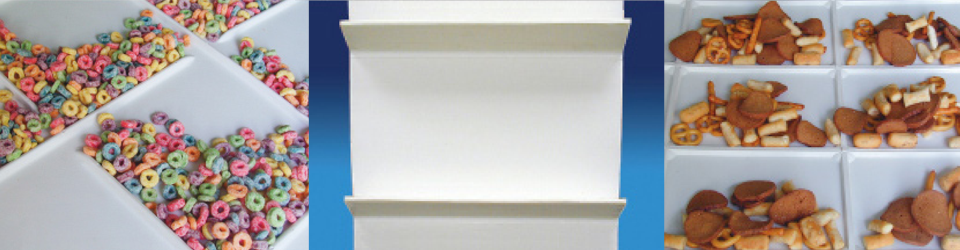

MIPR Corp will solve your cleated conveyor belting challenges across applications, including sizing, solid waste disposal, ditch-digging and road construction, roofing, scrap metal, die stamping, road scalping, FDA and food handling, and wide belt sanding.

MIPR Corp use rubber, nitrile, butyl and PVC belts and splice (horizontally or longitudinally) or mechanically fasten to configure the conveyor belting with the best performance characteristics for your application. From standard to one-of-a-kind, challenge us—you will find our staff extremely knowledgeable with more than 30 years of experience in an ever-changing field.

Contact MIPR Corp today to discuss your needs for cleated conveyor belting for your application. We carry a full-line of conveyor belts and belting.

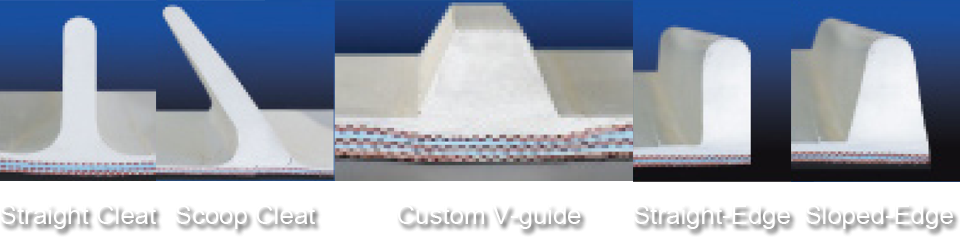

CLEATS – Cleats are used to convey material up an incline and prevent product rollback, as well as to create separation between the products or materials that are being conveyed. Other names for cleats include flights, lugs and profiles. We offer a wide variety of cleat styles and patterns to fit every application need.

MIPR Corp Cleat Types – At a Glance

Cleats are available in white FDA or black oil-resisting nitrile, black SBR rubber, as well as black and white butyl. Two part cleats consist of a rubber “foot” hot molded to the base belt and a bolted-in urethane blade that is used for heavy-duty applications. For more information, call MIPR Corp at 1-800-540-1846.

Rubber, Nitrile, Butyl and PVC Cleats

Standard I Cleats – Cleats can be molded to the belt surface on any center, to fit a wide variety of applications. Cleats come in heights from 1/2″ to 5″ (Beefy cleats to 6″).

- For conveying up steep inclines

- Available in white FDA or black oil-resisting nitrile, black SBR rubber, black and white butyl

- Cleats are hot molded into the belt surface (not cold bonded or cemented on)

Mini Cleats – Mini-cleats are low-profile cleats ideal for moving products up inclines in light-duty applications. Unique shape allows for standard idler support on returns. Dimensions are 3/16″ height, 3/16″ wide at base and 1/8″ radius.

Steel-Reinforced Cleats – Super-strong cleat for the most rugged applications. Each cleat features a steel reinforcement oriented to best counter the forces encountered in a particular application.

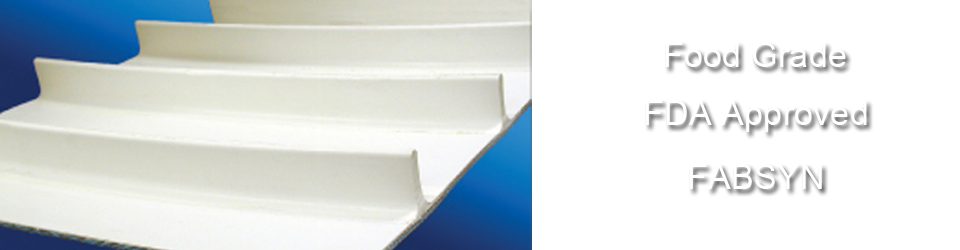

Curved PVC Cleats – Ideal cleat for many incline applications requiring food-grade belting. Cleats up to 3 tall are available in 45° and 30° configurations. Cleats can be applied to belts 6″ to 48″ wide and on centers as close as 4 1/2″ at 30° and 9″ at 45°.

PVC Scoot Cleats – White PVC cleats in an angled scoop form to improve capacity up steep inclines. Acceptable for food-handling applications. Available in 2″, 2 1/2″ and 3″ heights, the cleats are hot welded into the belt surface for a smooth seamless finish.

Beefy Cleats – Beefy cleats feature an extra-heavy cross section designed for heavy-duty, rugged applications. Thickness is double that of a standard I cleat. Available in heights from 1″ – 6″, with backup braces available with 2″ and 3″ heights.

High Incline Cleats – Aggressive scoop cleats for high-capacity conveying on steep inclines. C cleats are available in heights from 1″ to 5″, and S cleats come in heights of 4 1/2″ and 5 1/2″. Rugged cleats are hot vulcanized into the belt cover for long service.

Lug Cleats – Lug construction features rugged V-belt shapes for impact resistance. Available in A (1/2″ W x 5/16″ H), B (5/8″ W x 716″ H) and C (7/8″ W x 5/8″ H) cross sections.

PVC Vinyl Cleats – PVC cleats are welded to PVC belting to produce a rugged, economical combination ideal for wet, oily or acidic conditions. Available in black or white FDA compounds and can be spaced on any centers, indented, notched, cut down to intermediate heights and contain cut-outs.

PVC Extruded Cleats – Extruded PVC cleats conveniently packaged for distributors and OEM’s to manufacture their own PVC cleated belt. PVC cleats are furnished in convenient 100 foot rolls.

URETHANE CLEATS

Urethane Standard Cleat – Available in heights from 1/2″ to 6″, this is a super-strong, abrasion-resistant cleat. Angled backup support enables the cleat to carry a heavier load.

Urethane Square/Rectangular Cleat – Strong, abrasion-resistant urethane cleat. Available in any cross section.

Urethane Two-Part Cleat – For heavy-duty, high capacity applications. Unique two-part construction consist of a rubber “foot” hot molded to the base belt, and a bolted-in urethane cleat. Cleat can be replaced in high-wear applications. Heights from 5″ to 15 1/4″.

Urethane Chevron Cleat – A wide variety of custom patterns are available for durable incline conveying.

Lightweight HF Welded Cleats

High frequency (HF) welded profiles combine advanced technological features to optimize productivity, and provide quality custom products to meet your customers’ unique application needs. The HF welding process creates a strong, consistent bond between two polymers. This strong bond helps ensure food safety while offering protection from bacteria contamination. It’s also ideal for small parts, metals and plastics. HF welded features include:

- Stronger bond than traditional welding methods

- Longer service life

- Custom profiles available for specialty applications

- Easy cleaning

- Narrow-base widths to wrap smaller pulleys

- Thin line and footless cleats available

- Precision placement of cleats

- A variety of sizes and thicknesses available

Heavy-Duty Profiles & Cleats

MIPR Corp hot vulcanizes a variety of rubber cleat styles for styles for incline applications. We can customize the cleat configuration to meet your individual application needs.

Molded Road-Away Milling Belt – MIPR Corp’s integrally molded U-shaped and V-shaped chevron pattern belts offer high capacity and superior performance. MIPR Corp’s special endless splicing techniques assure excellent strength, flexibility and performance in these demanding applications.

- High-strength rubber compounds

- Rugged wide cleat base and tapered ends eliminate cleat separation from belt

- Will withstand the rigors of high speeds and small pulley diameters

- 1″ high cleats for more carrying capacity and better leveling of material on carrying side.

- Smoother, quieter return and better tracking thanks to the center stabilizer bar on the V-cleat construction

- Mechanical fasteners are also available

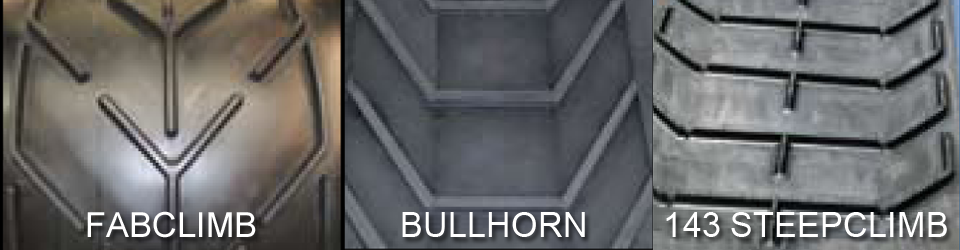

MOLDED CHEVRONS

MIPR Corp provides a variety of molded chevron cleat designs for demanding applications. The molded chevron profiles are an integral part of the top cover that ensures superior performance and durability.

Chevron Designs – Fully molded chevrons of various cross sections enable the conveying of wet and/or loose material up steep inclines. Chevrons can be made closed in the center or open for drainage. Chevrons also increase the amount of material moved by quick pick-up at the loading point.

Construction – All chevron cleat patterns utilize a patented, permanent heat-cured bonding process. Along with the high-grade rubber compounds used to create the cleats, this produces a truly rugged and long-wearing belt.

Applications – Popular applications include: sand and gravel, wood chip handling, minerals – such as coal and iron, heavy-duty scrap metal, road construction, waste management, barge and railroad car unloading.

Durocleat – Molded chevron cleated belt is available in six different specifications, with cleats in a uniform pattern running across the width of the belt.

- Cleat dimensions are 1/4″ high x 3/8″ wide x 6″ overall width

- This versatile V-cleat belt is available with rubber bottom covers, as well as bare back constructions for operating on metal beds

- Compounds include standard Grade 2 and MOR for oily conditions

- Durocleat is widely used for conveying grain, woodchips, sand, aggregate and refuse in recycling facilities

Durochev – Durochev belts have a 5/8″ high molded chevron cleats on 10″ centers. These belts are designed for rugged incline applications and popular for conveying rock, sand and gravel. The molded cleats are recessed from belt edges to allow for placement of skirting.

Rock Chucker – These fully molded chevron cleated belts are designed for “placing” product in confined/hard-to-reach areas. This versatile 2-ply belt is an excellent choice for throwing rock, sand, mulch, dirt and other bulk materials. MIPR Corp’s Rock Chucker belts are vulcanized endless to withstand the stress of high speeds and small pulley diameters. Belt width is 14 inches.

Popular applications include:

- Basement/foundations jobs

- Residential and commercial construction

- Landscaping maintenance and construction

- Driveway, sidewalk and curb construction

- Trenching for public utilities

MIPR Corp has over 150 patterns available but can customize them to your specific needs. Heights normally range from 1/3″ to 1 1/2″ to prevent rollback. Normal incline angels range from 15-35 degrees depending on material conveyed and surcharge angle. Chevron cleats are also used on flat idlers as well as metal beds or pan conveyors.

Rule of Thumb: Cleat height should be approximately 1/2 to 2/3 of the material size for uniform bulk material (such as sand and grain).

STEEP CLIMBER CLEAT PATTERNS

MIPR Corp’s Steep Climber hot vulcanized rubber cleats are specifically designed for the larger material and steeper incline angles used in troughing systems. This versatile and durable cleat pattern comes in four (4) widths: 13-27″. Cleat spacing is 10″ to ensure smooth running on return idlers.

HEAVY-DUTY DUROWALL CLEAT OPTIONS

MIPR Corp designed our Durowall belting with a variety of cleating styles and compounds to allow for maximum operational efficiency based on the required capacity and angle of inclination. Belting is available with both single-piece and two-piece combination cleats. Many of the larger cleats we provide are fabric reinforced to withstand punishment at loading points )two-piece cleat compounds include rubber, polyurethane, high-temp polyurethane and UHMW). Taller cleats are normally bolted to the sidewalls for additional strength and flexibility.

CORRUGATED SIDEWALLS

Durowall corrugated sidewalls (available in heights from 1″ to 12″) are manufactured in a variety of compounds to best suit your application needs. All of our corrugated sidewalls have high tensile strength properties for added flexibility and toughness in order to withstand cutting, tearing and abrasion. We also offer fabric reinforced sidewalls for products greater than 6″ tall to provide additional strength and tear resistance.

HEAVY-DUTY DUROWALL SIDEWALLS

Durowall is a major corrugated sidewall belting producer with a proven track record spanning almost 30 years. MIPR Corp has sold thousands of sidewall belts utilized in numerous applications including mining, power, waste water treatment, recycling, cement, tunneling, steel manufacturing and food processing. MIPR Corp’s exclusive sizing program can engineer a belt for any system.

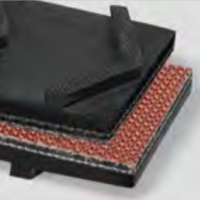

Cross-Rigid Base Belting

- Cross-rigid base belting helps deliver material in an efficient, cost-effective manner for applications that may challenge standard belts. That means a leaner, more efficient system without worry of belt failure or downtime.

- MIPR Corp’s Durowall cross-rigid belting is specifically designed to provide lateral stiffness and eliminate belt bowing and cupping at directional change points on the conveyor. It also helps reduce belt sag on the return run.

- Although the belt is rigid in the transverse direction, it remains flexible in the longitudinal direction. This unique design allows the belt to operate on standard pulleys and not interfere with the conveyor structure.

Durowall lightweight belts are popular for operating in confined areas, particularly when products need to be quickly elevated.

Various cleat sizes and styles are available. Sidewalls and cleats are also available in various colors.

FABLON HEAVY DUTY INTEGRALLY MOLDED CLEAT PATTERNS

Fablon heavy duty belts are designed to handle the aggressive transfer and elevation of materials such as sand, stone, gravel, recycled asphalt product (RAP) and other construction materials. Fablon’s unique cleat patterns are designed to lock free flowing materials to the belt surface, preventing “slip-back”. The cleats are nested in an overlapping pattern to maintain a smooth running surface on the return idlers.

Fablon heavy duty belts are different from other heavy duty cleated belts for these reasons:

- Cleats are integrally molded and become part of the belt cover. This feature eliminates cleat separation and allows the belt to navigate smaller pulleys.

- Advanced splicing techniques assure maximum strength and flexibility. High strength rubber compounds are used for superior impact resistance to both the belt and the cleats.

- Fablon offers 1/2″, 3/4″ and 1″ tall heavy duty molded cleat profiles on various center lines.

- Most popular Fablon heavy duty sizes are in stock, ready for immediate delivery

- Different base belt constructions are available, including 2 ply 220, 3 ply 240, 3 ply 330 and 2 ply 400, along with various cover gauges and compounds.

BULLHORN has a 1/2″ x 1/2″ low profile cleat molded on a 6″ center line that offers smooth delivery of planed asphalt, gravel, wood chips and is frequently used on stone slingers. Available in belt widths from 12″ to 60″ and cleat widths from 12″ to 48″.

BIGHORN offers a 3/4″ high x 3/4″ thick rounded cleat on 9″ centers. Used frequently for planed asphalt, sand, rock and heavy materials. Bighorn is easily troughed. Available in belt widths from 12″ to 60″ and cleat widths from 12″ to 48″.

FABCLIMB is made with abrasion resistant 1 1/4″ high tapered cleats with a “Y” cleat center pattern that increases production capacity. Two cleat widths are available: 31″ on 13″ centers, and 23″ on 12″ centers. Applications include wood chips, coal & salt, grain and construction materials.

FABLIFT‘s unique cleat design provides smooth, reliable product delivery in demanding incline applications such as transporting larger rock and recycled asphalt. It is made with a 1″ square cleat on 10″ centers along with a 1″ square continuous center rib for excellent support on the return. Available in belt & cleat widths up to 48″.

LONGHORN is made with a 1″ high tapered “gum drop” cleat using a staggered chevron pattern on 12″ centers. The offset overlap pattern is designed for easy handling of heavy wet materials such as sand. Available in belt and cleat widths up to 48″.

Heavy Duty Fablon In-Stock Profile Belts

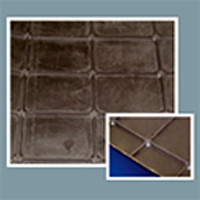

FABLON heavy duty profile belts are manufactured from heavy duty synthetic fabric with high-grade MOR covers and cleats. Two heavy duty patterns are in stock and available for immediate delivery. These are: (1) TOP FLIGHT pattern; lateral cleats 3/16″ high on 6″ centers; longitudinal cleats 3/16″ high on 4″ centers; raised buttons at the corners of the pattern allow for drainage of wet product; patented design runs on all types of conveyors without special idlers; and (2) the CROSSTOP pattern; cleats 3/8″ x 3/8″ taper to 1/4″; open 8″ x 8″ pattern allows water drainage and ease of cleaning. Both belts operate like a flat belt, with constant support from the conveyor return idlers. These belts have a working strength PIW of 150 lbs.

LACING & SPLICING CONVEYOR BELTING

Selecting the correct lacing option for your belt is critical. MIPR Corp offers a variety of lacing styles and materials to meet the needs of every application.

CUSTOM SPLICING OPTIONS:

Recessed Lace: Mechanical splice area is recessed below the belt surface.

Overflap: Mechanical lacing is installed below the belt surface and the top cover is separated from the belt carcass creating a flap over. The cover can be glued down after installation.

Hidden Lace: Mechanical fasteners are installed below the belt cover to prevent the lace from contacting the product.

Finger Hinge Lace: Finger hinge lace is equipped with flexible, hinged plastic lacing, creating an easy, quick repair alternative to endless belts. FHL requires the belt be made of PVC or polyurethane, have a thickness of .08″ to .263″, have a minimum belt length of 55″, and a maximum belt width of 40″.

Thermoplastic Hinge: Thermoplastic hinge lace is made with the same homogenous material as your belt. This lace is welded to the belt and connect with a metal or nylon pin. Nylon pins should be used when metal detectors are required. (This option is available for Volta products only.)

ENDLESS NON-MECHANICAL SPLICING SOLUTIONS

Endless splicing methods eliminate the need for hardware fasteners. This fabrication technique is excellent for food processing and applications where products need to be handled with greater care.

Step Splice Belt: For belts with multiple plies. Plies are separated and “stepped” to interlock with one another at the splice point. Performed by experts in our fabrication facilities for quality assurance and appropriate curing time.

Skived Splice: A precision grinding technique is used to achieve uniform thickness at the splice point for a variety of applications.

Finger Splice: For thermoplastic, urethane and PVC belts. A very durable splice that maintains a smooth belt surface throughout the splice area. Multiple finger patterns are available to meet a variety of applications and system pulley sizes.

Endless-Prepared: We square and prepare the belt’s ends in our fabrication facilities for hot or cold cement bonding at the customer’s site. (Cement bonding kits with instructions are available.)

Double Finger Splice: Unlike a standard finger splice, fingers are cut from multiple plies, staggered, then fused together by heat and pressure to create a stronger, more flexible splice.

Stitched Reinforcement: Certain applications put unusual wear on splices and edges. These areas can be strengthened with stitching.

Longitudinal Splicing: Very wide belts are created by longitudinally splicing two or more belts of narrower dimension. Plies are expertly stepped and bonded in our fabrication facilities to create a uniformly smooth belt as wide as the application requires. Ultra-wide belts can be made endless prior to shipping or have ends prepared for field splicing. V-guides and other profiles can also be added.